Top 10 Portable Rock Crusher Models for Your Crushing Needs?

When it comes to the world of portable rock crushers, industry expert John Doe notes, "The right model can transform your operations." Portable rock crushers are crucial for various applications. They provide mobility and efficiency while reducing material on-site. With so many options available, selecting the right model can be challenging.

Many individuals may feel overwhelmed by the choices. They could overlook essential features that match their specific needs. Portable rock crushers vary in size, power, and capabilities. It's important to consider what each model offers before making decisions.

In the landscape of construction and mining, the right portable rock crusher can make or break a project. Selecting a model that fits your needs isn't easy. It requires careful evaluation of your requirements and the equipment's capabilities. Ultimately, the right choice can enhance productivity and efficiency in your operations.

Overview of Portable Rock Crushers and Their Applications

Portable rock crushers are essential tools in various applications. They allow for efficient material processing in remote locations. Contractors, landscapers, and small miners benefit greatly from these machines. Their mobility provides flexibility, allowing users to crush rocks on-site rather than transporting heavy materials elsewhere.

Choosing the right model is crucial. Different models vary in size, power, and crushing capacity. Understanding your specific needs helps narrow down options. For example, some models are better suited for hard rock, while others excel with softer materials. Evaluating the types of materials you'll encounter is important.

Tips: Consider weight and portability when selecting a crusher. A lighter model is easier to transport but may sacrifice power. Also, think about the ease of maintenance. Some machines require more frequent upkeep than others. Lastly, take into account noise levels, especially when working in residential areas. Balancing performance and practicality ensures you find a suitable option for your crushing tasks.

Key Features to Consider When Choosing a Portable Rock Crusher

When choosing a portable rock crusher, several key features come into play. Understanding the size and weight is crucial. A lighter model will be easier to transport and set up. However, smaller units might lack power. Consider the material you will be crushing. Some crushers perform better with harder rocks, while others are suited for softer materials.

The fuel type is another important factor. Gasoline models are often more mobile. Electric crushers can be quieter and easier to maintain. Additionally, examine the output size of crushed material. A good model should provide adjustable settings to achieve different sizes. Don’t overlook safety features. Ensure the design minimizes risk during operation. Check for emergency shut-off options too.

Also, inspect the warranty and support offered by the manufacturer. A solid warranty can save money down the line. It's essential to reflect on your actual needs versus the specifications. Sometimes, a more powerful model isn't necessary. Balancing power with portability is a common consideration. Your choice should match your specific crushing goals.

Top 10 Portable Rock Crusher Models for Your Crushing Needs

| Model |

Weight (lbs) |

Crushing Capacity (tons/hr) |

Power (HP) |

Key Features |

| Model A |

150 |

5 |

5 |

Compact design, easy mobility |

| Model B |

200 |

8 |

7 |

High crushing efficiency, adjustable output size |

| Model C |

250 |

10 |

10 |

Durable construction, enhanced productivity |

| Model D |

180 |

6 |

6 |

Simple operation, easy maintenance |

| Model E |

220 |

9 |

8 |

Versatile use, suitable for various materials |

| Model F |

300 |

12 |

12 |

Heavy-duty, perfect for large projects |

| Model G |

170 |

5 |

5 |

User-friendly interface, portable |

| Model H |

240 |

11 |

9 |

Quick setup, efficient crushing |

| Model I |

210 |

7 |

7 |

Noise-reduction features, innovative design |

| Model J |

230 |

10 |

8 |

Excellent mobility, robust performance |

Top 10 Portable Rock Crusher Models and Their Specifications

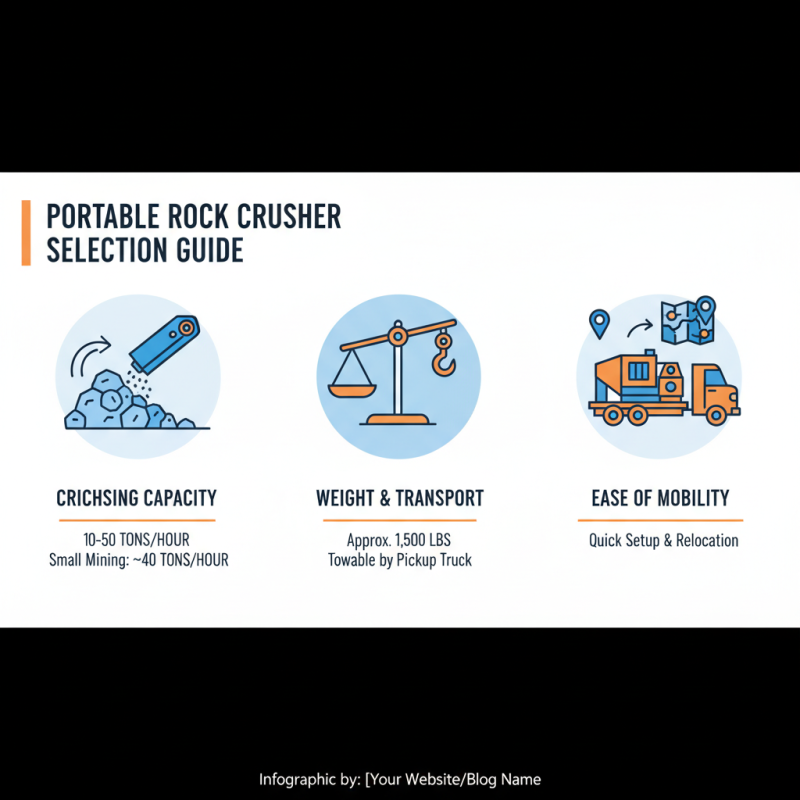

When selecting a portable rock crusher, specifications are critical. The key metrics to consider include crushing capacity, weight, and ease of transportation. Most models range in capacity from 10 to 50 tons per hour. For instance, a model with a 40-ton capacity can efficiently handle a small mining operation. Weighing around 1,500 pounds, some crushers can be easily towed by a standard pickup truck.

Tips: Always check the mobility features. Some units have tracks for easy maneuverability on-site. This can save valuable time during operations.

Another important specification is the input size of the material. Many crushers accommodate rocks up to 12 inches in diameter. Real-world data shows that portable models typically offer a reduction ratio of about 12:1. This means they effectively reduce large rocks into manageable sizes for further processing. However, a few models might struggle with softer materials, leading to uneven crushing.

Tips: Ensure the model you choose matches your material type to avoid inefficient operations. Review user feedback for real-life performance insights, as specifications can sometimes mislead.

Comparative Analysis of Each Model's Performance and Pricing

When assessing portable rock crushers, performance and pricing are crucial factors. Each model brings unique capabilities to the table. For instance, some may crush harder rocks but at a higher price. Others offer lower power but are budget-friendly. This creates a complex dilemma for buyers.

Let’s consider the crushing capacity and size. A lightweight model may be easier to transport but might compromise efficiency. On the other hand, heavier models often deliver better results but can be cumbersome. Users must weigh these trade-offs. The operational costs also deserve attention. Frequent maintenance could add to overall expenses.

Additionally, user experiences reveal disparities in durability. Some models may face wear and tear issues, leading to unexpected downtimes. This aspect can influence long-term pricing strategies. Finding a perfect balance between initial cost and operational reliability can be challenging. Thus, careful analysis is essential before making a purchase decision.

Maintenance Tips for Prolonging the Life of Your Portable Rock Crusher

Proper maintenance of your portable rock crusher is essential for longevity. Start by regularly inspecting the components. Check for any signs of wear or damage. Loose parts can lead to significant issues later. Keep the crusher clean, especially after heavy use. Dust and debris can accumulate, leading to overheating or mechanical failures.

Lubrication is crucial. Use the recommended lubricant for bearings and gears. This helps reduce friction and wear. Monitor hydraulic fluids as well. Low levels can cause inefficient operation. It's easier to prevent problems than to fix them later.

Also, consider the environment where you operate the crusher. Extreme temperatures can affect performance. Adjust your maintenance schedule if operating in harsh conditions. Periodic training on operational best practices can also prove beneficial. Understand your equipment well. The better you know it, the easier it is to maintain.

Home

About Us

Products

Concrete Mixing Plant

Concrete Mixing Plant

HZS Series Belt Concrete Mixing Plant

HZS Series Belt Concrete Mixing Plant

HZS Series Bucket-Lifting Type Container Concrete Mixing Plant

HZS Series Bucket-Lifting Type Container Concrete Mixing Plant

HZS60 Mobile Concrete Mixing Plant

HZS60 Mobile Concrete Mixing Plant

HZS Series Bucket-Lifting Type Concrete Mixing Plant

HZS Series Bucket-Lifting Type Concrete Mixing Plant

HZS Series Mobile Concrete Mixing Plant

HZS Series Mobile Concrete Mixing Plant

HZS Series Top-Mounted Concrete Mixing plant

HZS Series Top-Mounted Concrete Mixing plant

HZS Series Semi-Top Mounted Concrete Mixing Plant

HZS Series Semi-Top Mounted Concrete Mixing Plant

Stabilized Soil Mixing Plant

Stabilized Soil Mixing Plant

Asphalt Mixing Plant

Asphalt Mixing Plant

Sand & Gravel Crushing and Screening Plant

Sand & Gravel Crushing and Screening Plant

RTPF350DS Crawler Mobile Impact Crushing Plant

RTPF350DS Crawler Mobile Impact Crushing Plant

RT116JH Crawler Mobile Jaw Crushing Plant

RT116JH Crawler Mobile Jaw Crushing Plant

RT116JE Crawler Mobile Jaw Crushing Plant

RT116JE Crawler Mobile Jaw Crushing Plant

RT300CE Crawler Mobile Cone Crushing Plant

RT300CE Crawler Mobile Cone Crushing Plant

RT300CH Crawler Mobile Cone Crushing Plant

RT300CH Crawler Mobile Cone Crushing Plant

RT5015H Mobile Scalping Screen

RT5015H Mobile Scalping Screen

RT315VSIE Crawler Mobile Sand Maker

RT315VSIE Crawler Mobile Sand Maker

RT3YK6020 Crawler Mobile Screening Plant

RT3YK6020 Crawler Mobile Screening Plant

RT3YK6020M Modular Screening Plant

RT3YK6020M Modular Screening Plant

RTF260M Modular Counterattack Crushing and Screening Integrated Machine

RTF260M Modular Counterattack Crushing and Screening Integrated Machine

RTF350M Modular Impact Crushing Plant

RTF350M Modular Impact Crushing Plant

RTF450M Modular Impact Crushing Plant

RTF450M Modular Impact Crushing Plant

Construction Waste Resourceful Treatment Line

Construction Waste Resourceful Treatment Line

Performances

Video

News

Contact Us

WDB Series Foundation-Free Stability Soil Mixing Plant

WDB Series Foundation-Free Stability Soil Mixing Plant LCB Series Emulsified Asphalt Cold Regeneration Secondary Mixing Plant

LCB Series Emulsified Asphalt Cold Regeneration Secondary Mixing Plant LB Series Asphalt Mixing Plant

LB Series Asphalt Mixing Plant LBR Series Integrated Asphalt Mixing Plant

LBR Series Integrated Asphalt Mixing Plant LBRN Series Counterflow Integral Asphalt Mixing Plant

LBRN Series Counterflow Integral Asphalt Mixing Plant RZS Series Asphalt Mixing Plant

RZS Series Asphalt Mixing Plant RTZS120 Series RAP Crushing & Screening Plant

RTZS120 Series RAP Crushing & Screening Plant Construction Waste Resourceful Treatment Line

Construction Waste Resourceful Treatment Line